-

Ningbo Torgwin Import & Export Co., Ltd

-

-

Ningbo Torgwin Import & Export Co., Ltd

-

Ningbo Torgwin Import & Export Co., Ltd

Ningbo Torgwin Import & Export Co., Ltd

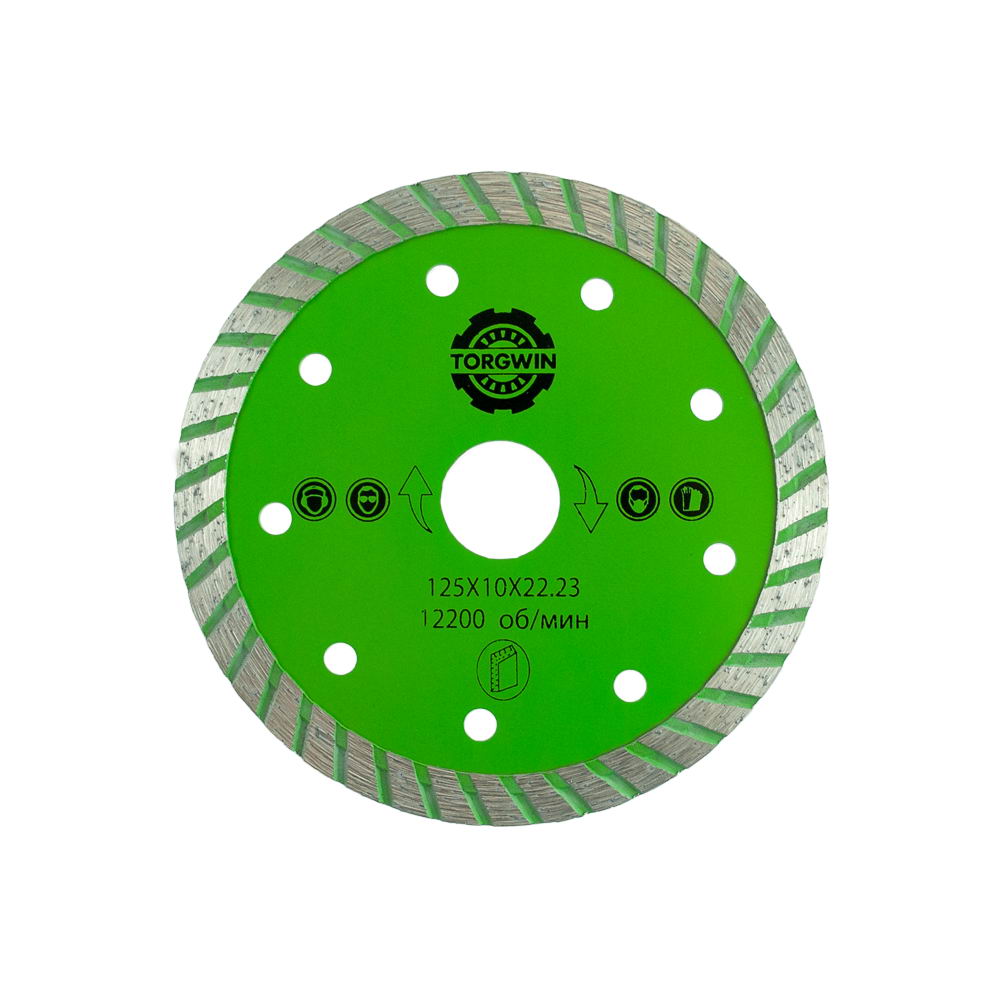

Cold Pressed Sintered Turbo Saw Blade

1.For general purpose cutting, bricks, concrete, marble, granite, stone ,etc ;

2.Dry cutting & Wet cutting;

3.Faster cutting speed & longer life;

4.Cold pressed process, low cost;

5.OEM according to customer's requirements.

6.Suitable for angle grinder, circular saw, table saw, etc.

Diamond saw blades are widely used in the processing of hard and brittle materials such as concrete, refractory, stone, ceramics and so on. Diamond saw blade is mainly composed of two parts:basal body and diamond tips.

According to the classification of cutting objects, we can divide them into general blades and professional blades.

Process classification

1. Sintered diamond saw blade: it is divided into cold press sintering and hot press sintering.

2. Welding diamond saw blade: it is divided into high frequency welding and laser welding. High frequency is to weld the tipes with the basal body through high-temperature molten medium; In laser welding, the contact edge between the tips and the substrate is melted by high temperature laser beam to form metallurgical bonding.

3. Vacuum brazed saw blade.

Appearance classification

1. Segmented saw blade: the sawtooth is broken and the cutting speed is fast. It is suitable for dry and wet cutting methods.

2. Continuous edge saw blade: continuous sawtooth diamond saw blade is generally made by sintering method. Bronze bond is commonly used as the basic matrix material. Water must be added during cutting to ensure the cutting effect, and laser is used to cut the gap.

3. Turbo saw blade: combined with the advantages of the previous 1 and 2, the sawtooth continuously presents turbo shape, uniform convex and concave, which improves the cutting speed and increases the service life.

Different kinds of diamond saw blades are selected for different materials, and different powder formulations are suitable for the characteristics of different materials, which has a direct impact on the quality, effect, qualified rate and even cost and benefit of material products.

The factors affecting the efficiency and service life of diamond circular saw blade include sawing process parameters, diamond particle size, concentration, bond hardness and so on. According to the cutting parameters, there are saw blade linear speed, sawing concentration and feed speed.

Sizes as following:

< Previous message

Next message >

Power by: cnwangju.com Sitemap